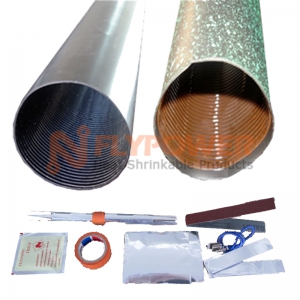

Cable Repair sleeve BH-RSW

- Applications: BH-RSW Cable Repair Sleeve which provides exceptional benefits in the repair and retrofit protection of aging cable infrastructures without disconnection of service.

- Characteristics: Reduces total installed costs by 80%,eliminates system downtime during installation; Provides moisture proof seal with a fully encapsulating hot melt adhesive; Offers quick and easy application using an innovative closure mechanism.

- Operating temperature range: Minimum fully recovery temperature: 120oC

- Approvals / Specifications: RoHS

- Colors: Black

|

Model No. |

As supplied Min. ID(mm) |

After covered Max ID(mm) |

Standard Length(mm) |

Application for cable OD(mm) |

|

BH-RSW 22/6-500 |

22 |

6 |

500 |

7~15 |

|

BH-RSW 36/10-500 |

36 |

10 |

500 |

12~20 |

|

BH-RSW 50/15-600 |

50 |

15 |

600 |

20~40 |

|

BH-RSW?60/18-700 |

60 |

18 |

700 |

30~50 |

|

BH-RSW?70/22-800 |

70 |

22 |

800 |

35~60 |

|

BH-RSW?80/25-900 |

80 |

25 |

900 |

40~70 |

|

BH-RSW 100/30-900 |

100 |

30 |

900 |

50~90 |

|

BH-RSW 135/35-900 |

135 |

38 |

900 |

60~120 |

|

BH-RSW 164/45-900 |

164 |

45 |

900 |

80~150 |

|

BH-RSW 185/55-900 |

185 |

55 |

900 |

90~170 |

|

BH-RSW 200/60-900 |

200 |

60 |

900 |

100~180 |

|

BH-RSW 220/65-900 |

220 |

65 |

900 |

120~210 |

|

BH-RSW 240/70-1000 |

240 |

70 |

1000 |

130~220 |

|

BH-RSW 260/75-1000 |

260 |

75 |

1000 |

150~240 |

|

BH-RSW 280/80-1000 |

280 |

80 |

1000 |

180~260 |

|

BH-RSW 300/85-1000 |

300 |

85 |

1000 |

200~280 |

Remarks:

1. Special size, cut pieces are available on request;

2. Accessories: Heat shrinkable sleeve,stainless steel channel clip,?cleaning tissue, aluminum foil,sandper.

|

Property |

Test Method |

Typical Data |

|

Tensile Strength? |

ISO 37? |

17 MPa min.? |

|

Ultimate Elongation? |

ISO 37? |

350% min.? |

|

Density? |

ISO 1183 Method A? |

1.0 – 1.2 g/cm3? |

|

Hardness? |

ISO 868? |

50 – 70 D? |

|

Accelerated Aging? |

7 days at 150℃±2℃ ISO 188? |

|

|

Tensile Strength ISO 37?? |

14 MPa min.? |

|

|

Ultimate Elongation?ISO 37? |

300% min.? |

|

|

Thermal Endurance? |

IEC 60216? |

120℃? |

|

Low Temperature Flexibility? |

4 hours at –40℃±3℃ |

No cracking? |

|

ASTM D2671 Procedure C? |

||

|

Dielectric Strength |

IEC 60243? |

1 mm 180kV/cm |

|

min. 3.5 mm |

||

|

120kV/cm min. |

||

|

Volume Resistivity? |

IEC 60093? |

1 x 1012Ω cm min.? |

|

Dielectric Constant? |

IEC 60250? |

5 max.? |

|

Water Absorption? |

?14 days at 23℃±2℃ ISO 62 Method? |

0.5% max.? |

|

Resistance to Liquids? |

7 days in transformer oil |

|

|

at 23℃±2℃(VDE 0370) ISO 1817? |

||

|

Tensile Strength?ISO 37? |

14 MPa min.? |

|

|

Ultimate Elongation ISO 37? |

300% min.? |

|

|

Resistance to Fungi? |

ASTM G21? |

Pass Rating 1? |