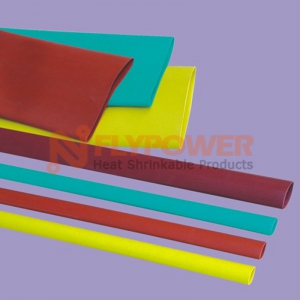

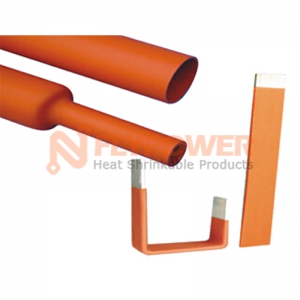

LOW SMOKING HALOGEN FREE FLAME RETARDANT HEAT SHRINKABLE TUBING SHRINK RATIO 2:1 BH-2(HF)

- Applications: Low smoking halogen free flame retardant heat shrinkable tubing widely used in electron, communication and automobile industry.

- Characteristics: As a kind of totally environmental friendly heat-shrinkable tube, it is made with specially designed halogen free polyolefin. It produces neither toxic smoke nor harmful substance when burning, which meets the growing demand of environmental protection all over the world. Except the common fine physical and chemical specifications, the tube also shows excellent flame-retardant, insulation, low temperature shrinking and flexible properties

-

Operating temperature range: Minimum shrink temperature: 65℃

Minimum fully recovery temperature: 95℃ - Approvals / Specifications: CE,RoHS

- Colors: Black, White, Other colors available on request

|

Normal Size(mm) |

As supplied(mm) |

After recovered (mm) |

Standard length(m/spool) |

||

|

Inside diameter(mm) |

Wall thickness(mm) |

Inside diameter(Max.) |

Wall thickness(mm) |

||

|

Φ1.0 |

1.5±0.2 |

0.18 |

0.50 |

0.33 |

200 |

|

Φ1.5 |

2.0±0.2 |

0.18 |

0.75 |

0.36 |

200 |

|

Φ2.0 |

2.7±0.2 |

0.25 |

1.00 |

0.44 |

200 |

|

Φ2.5 |

3.1±0.2 |

0.25 |

1.25 |

0.44 |

200 |

|

Φ3.0 |

3.7±0.3 |

0.25 |

1.50 |

0.44 |

200 |

|

Φ3.5 |

4.0±0.3 |

0.25 |

1.75 |

0.44 |

200 |

|

Φ4.0 |

4.7±0.3 |

0.25 |

2.00 |

0.44 |

200 |

|

Φ5.0 |

5.6±0.3 |

0.25 |

2.50 |

0.56 |

100 |

|

Φ6.0 |

6.8±0.3 |

0.25 |

3.00 |

0.56 |

100 |

|

Φ7.0 |

7.7±0.3 |

0.25 |

3.50 |

0.56 |

100 |

|

Φ8.0 |

8.8±0.3 |

0.30 |

4.00 |

0.56 |

100 |

|

Φ9.0 |

9.8±0.3 |

0.30 |

4.50 |

0.56 |

100 |

|

Φ10 |

10.7±0.4 |

0.30 |

5.00 |

0.56 |

100 |

|

Φ11 |

11.7±0.4 |

0.30 |

5.50 |

0.56 |

100 |

|

Φ12 |

12.7±0.4 |

0.30 |

6.00 |

0.56 |

50 |

|

Φ13 |

13.7±0.4 |

0.30 |

6.50 |

0.65 |

50 |

|

Φ14 |

14.7±0.4 |

0.35 |

7.00 |

0.69 |

50 |

|

Φ15 |

15.7±0.5 |

0.35 |

7.50 |

0.69 |

50 |

|

Φ16 |

16.7±0.5 |

0.35 |

8.00 |

0.69 |

50 |

|

Φ18 |

19.0±0.5 |

0.40 |

9.00 |

0.80 |

50 |

|

Φ20 |

21.4±0.5 |

0.40 |

10.00 |

0.80 |

50 |

|

Φ22 |

23.4±0.6 |

0.45 |

11.00 |

0.80 |

50 |

|

Φ25 |

26.5±0.8 |

0.45 |

12.50 |

0.90 |

50 |

|

Φ28 |

29.5±0.8 |

0.45 |

14.00 |

0.90 |

50 |

|

Φ30 |

31.5±0.8 |

0.45 |

15.00 |

0.90 |

50 |

|

Φ35 |

36.5±0.8 |

0.50 |

17.50 |

0.90 |

50 |

|

Φ40 |

42.0±0.8 |

0.50 |

20.00 |

1.00 |

50 |

|

Φ50 |

52.0±0.8 |

0.50 |

25.00 |

1.00 |

50 |

|

Φ60 |

62.0±1.0 |

0.50 |

30.00 |

1.00 |

30 |

|

Φ70 |

72.0±1.0 |

0.50 |

35.00 |

1.20 |

30 |

|

Φ80 |

82.0±1.0 |

0.55 |

40.00 |

1.20 |

30 |

|

Φ100 |

102.0±1.0 |

0.55 |

50.00 |

1.30 |

30 |

|

Φ125 |

126.0±1.0 |

0.55 |

60.00 |

1.30 |

15 |

|

Φ150 |

152.0±1.0 |

0.55 |

75.00 |

1.30 |

15 |

Special size, cut pieces are available on request.

|

Property |

Test Method |

Typical Data |

|

Operating temperature |

IEC 216 |

-55 to +105℃ |

|

Tensile strength |

ASTM D 2671 |

>10.4MPa |

|

Elongation at break |

ASTM D 2671 |

200% |

|

Longitudinal shrinkage |

UL224 |

±3% |

|

Eccentricity |

ASTM D 2671 |

≤30% |

|

Heat shock

|

250℃/4hrs

|

No crack No dropping |

|

Heat aging Tensile strength Ultimate elongation

|

136℃/168hrs

|

9.0MPa >150% |

|

Flammability

|

SAE-AMS-DTL-23053/5 |

Pass

|