{tab=Specification}

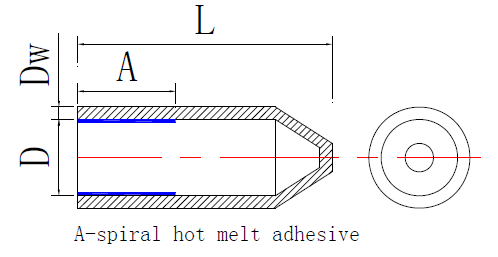

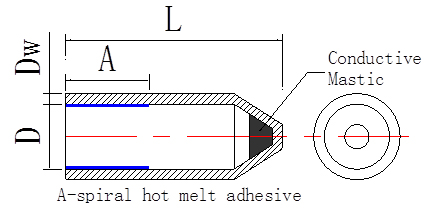

| Part Number | As supplied (mm) | After recovered | Conductive Mastic weight | Cable diameter (mm) | |||

| D(min) | A(±10%) | D(Max.) | L(±10%) | Dw(±20%) | |||

| BH-CEC 68-25/8.5 | 25 | 30 | 8.5 | 68 | 2.8 | 6±1g | 10-20 |

| BH-CEC 90-40/15 | 40 | 40 | 15 | 90 | 3.3 | 10±1g | 18-34 |

| BH-CEC 110- 42/15 | 42 | 40 | 15 | 110 | 3.3 | 10±1g | 25-48 |

| BH-CEC140-55/23 | 55 | 70 | 23 | 140 | 3.8 | 20±2g | 25-55 |

| BH-CEC 140-62/23 | 62 | 70 | 23 | 140 | 3.8 | 25±2g | 42-68 |

| BH-CEC 170-75/36 | 75 | 70 | 36 | 170 | 4.2 | 30±3g | 45-68 |

| BH-CEC-155-100/47 | 100 | 65 | 47 | 155 | 4 | 35±4g | 50-90 |

{tab=Technical Data}

| Property | Test Method | Typical Data |

| Operating temperature | IEC 216 | -55℃to +110℃ |

| Tensile strength | ASTM D 638 | >14 MPa |

| Elongation at break | ASTM D 638 | >400% |

| Density | ASTM D 792 | 1.05 |

| Elongation at break after aging | 150℃/168hrs | >300% |

| Dielectric strength | IEC 243 | >15KV/mm |

| Volume resistance | IEC 93 | >1014Ω.cm |

{/tabs}