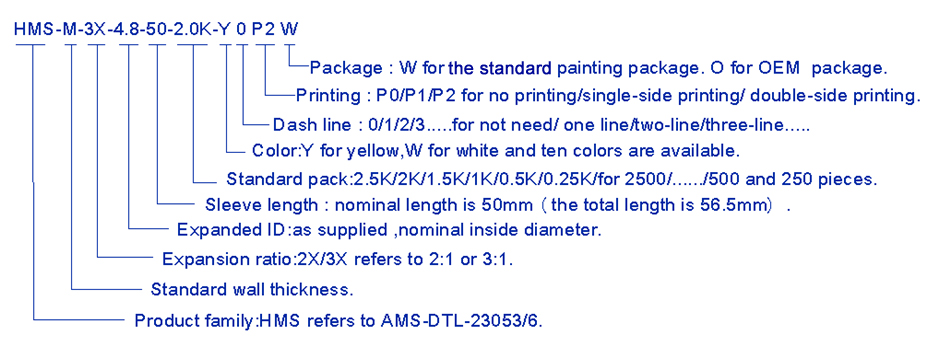

Halogen-free, Low Smoke Emission, Highly Flame ?Retardant Heat Shrink Marker Sleeve BH-DIN

Halogen free low smoke emission materials, designed ideally for motor train unit,rail transit, aerospace, and shipbuilding industries

?

?

{tab=Specification}

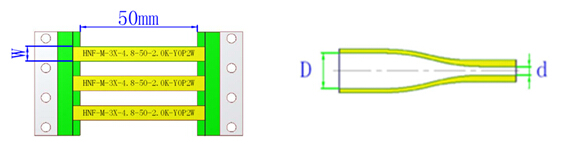

BH-DIN Shrink ratio-2X:

| Part Number | As Supplied (mm) | After Recovery(mm) |

| ID(D) | Flatten Width(w) | Double Wall Thickness | ID(d) | Single Wall Thickness |

| DIN-2X-1.6- | 2.00±0.20 | 3.7±0.3 | 0.48±0.10 | ≤0.79 | 0.45±0.06 |

| DIN-2X-2.4- | 2.79±0.20 | 5.0±0.3 | 0.48±0.10 | ≤1.18 | 0.49±0.06 |

| DIN- 2X-3.2- | 3.64±0.23 | 6.3±0.4 | 0.48±0.10 | ≤1.59 | 0.51±0.06 |

| DIN- 2X-4.8- | 5.26±0.25 | 8.9±0.4 | 0.49±0.10 | ≤2.36 | 0.54±0.06 |

| DIN- 2X-6.4- | 6.92±0.28 | 11.5±0.4 | 0.50±0.10 | ≤3.18 | 0.56±0.06 |

| DIN- 2X-9.5- | 10.2±0.32 | 16.7±0.5 | 0.51±0.11 | ≤4.75 | 0.59±0.06 |

| DIN- 2X-12.7- | 13.5±0.36 | 21.8±0.6 | 0.52±0.11 | ≤6.35 | 0.60±0.07 |

| DIN- 2X-19- | 20.1±0.40 | 32.2±0.6 | 0.53±0.11 | ≤9.53 | 0.62±0.07 |

| DIN- 2X-25- | 26.7±0.45 | 42.5±0.7 | 0.55±0.12 | ≤12.7 | 0.63±0.07 |

| DIN- 2X-38- | 39.8±0.51 | 63.2±0.8 | 0.57±0.12 | ≤19.1 | 0.64±0.07 |

| DIN- 2X-51- | 53.0±0.56 | 83.9±0.9 | 0.58±0.13 | ≤25.4 | 0.64±0.08 |

| DIN- 2X-76- | 79.4±0.56 | 125.3±1.0 | 0.59±0.13 | ≤38.1 | 0.64±0.09 |

?

?BH-DIN Shrink ratio-3X:?

| Part Number | As Supplied (mm) | After Recovery(mm) |

| ID(D) | Flatten Width(w) | Double Wall Thickness | ID(d) | Single Wall Thickness |

| DIN- 3X-1.6- | 2.00±0.20 | 3.7±0.3 | 0.47±0.10 | ≤0.53 | 0.52±0.06 |

| DIN- 3X-2.4- | 2.79±0.20 | 5.0±0.3 | 0.47±0.10 | ≤0.79 | 0.57±0.06 |

| DIN- 3X-3.2- | 3.64±0.23 | 6.3±0.4 | 0.48±0.10 | ≤1.06 | 0.61±0.06 |

| DIN- 3X-4.8- | 5.26±0.25 | 8.9±0.4 | 0.49±0.10 | ≤1.59 | 0.67±0.06 |

| DIN- 3X-6.4- | 6.92±0.28 | 11.5±0.4 | 0.50±0.10 | ≤2.36 | 0.71±0.06 |

| DIN- 3X-9.5- | 10.2±0.32 | 16.7±0.5 | 0.52±0.11 | ≤3.18 | 0.77±0.06 |

| DIN- 3X-12.7- | 13.5±0.36 | 21.8±0.6 | 0.53±0.11 | ≤4.75 | 0.80±0.07 |

| DIN- 3X-19- | 20.1±0.40 | 32.2±0.6 | 0.55±0.11 | ≤6.35 | 0.84±0.07 |

| DIN- 3X-25- | 26.7±0.45 | 42.5±0.7 | 0.56±0.12 | ≤8.47 | 0.86±0.07 |

| DIN- 3X-38- | 39.8±0.51 | 63.2±0.8 | 0.57±0.12 | ≤12.9 | 0.89±0.07 |

| DIN- 3X-51- | 53.0±0.56 | 83.9±0.9 | 0.57±0.13 | ≤17.2 | 0.90±0.08 |

| DIN- 3X-76- | 79.4±0.56 | 125.3±1.0 | 0.57±0.13 | ≤25.8 | 0.92±0.09 |

?{tab=Technical Data}

| Material | The sleeving shall be fabricated from irradiated, thermally stabilized and flame retarded modified polyolefin compound containing no halogens or cadmium in the formulation. |

| Application range | Industrial environment ; Rail & mass transit; Aerospace & defense; Marine; |

| Operating temperature range | -40---+125℃ |

| Minimum recovery temperature | +85℃ |

| Maximum storage temperature | +50℃ |

| Shrink ratio | 2:1, 3:1 |

| Components | Halogen-free |

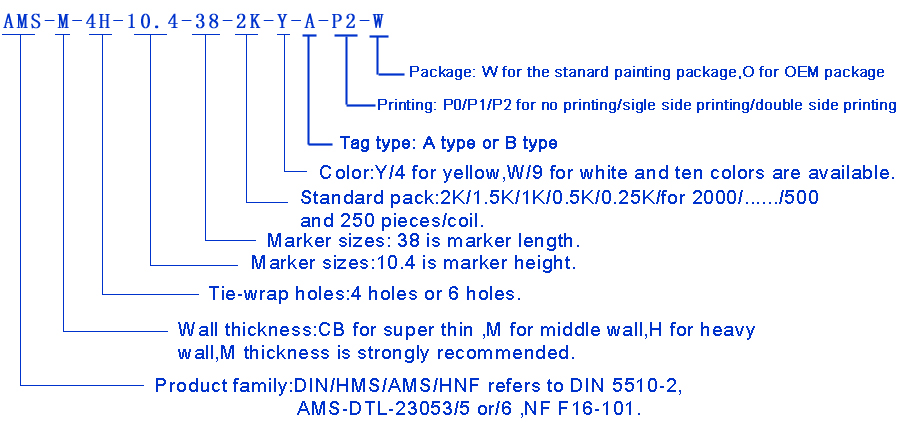

| Color | White, Yellow, other color is available if ordered |

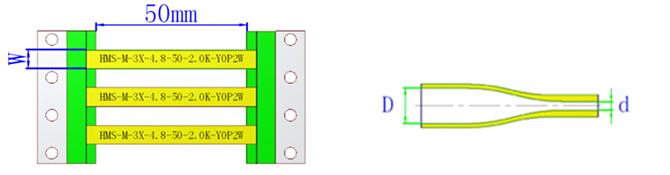

| Printing mode | Single sided printing and Double sided printing formats available |

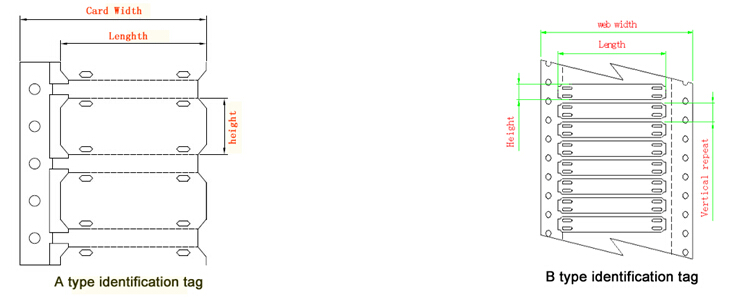

| Supplied mode | Either Continuous type or Ladder format type is available |

| Recommended Printers | Thermal transfer printer |

| Recommended Ribbons | WO-80500BK resin ribbon, Black, 100mm(width)*300m(length) |

?{/tabs}