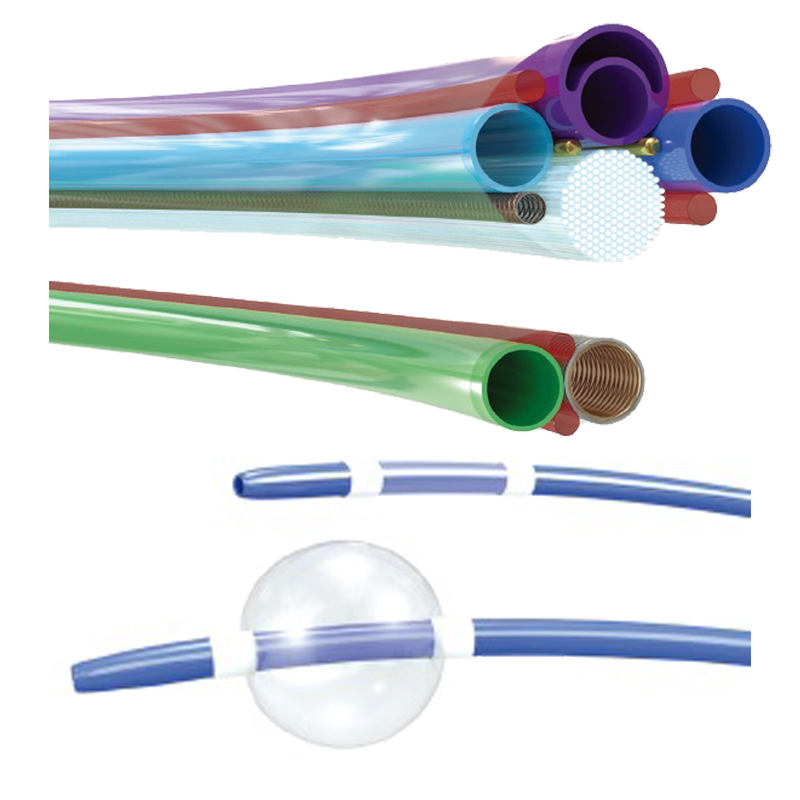

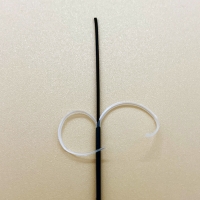

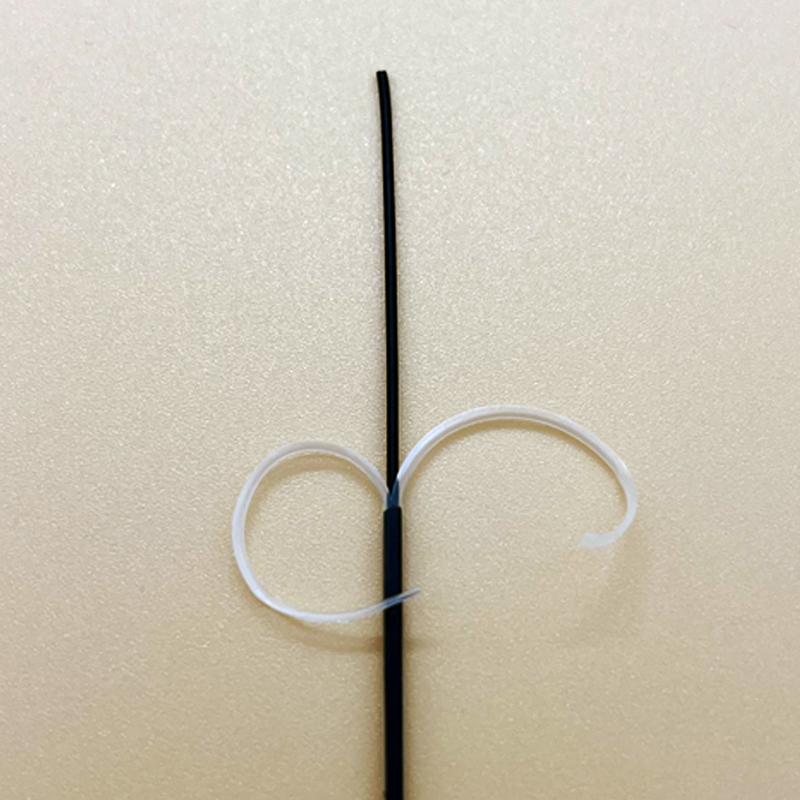

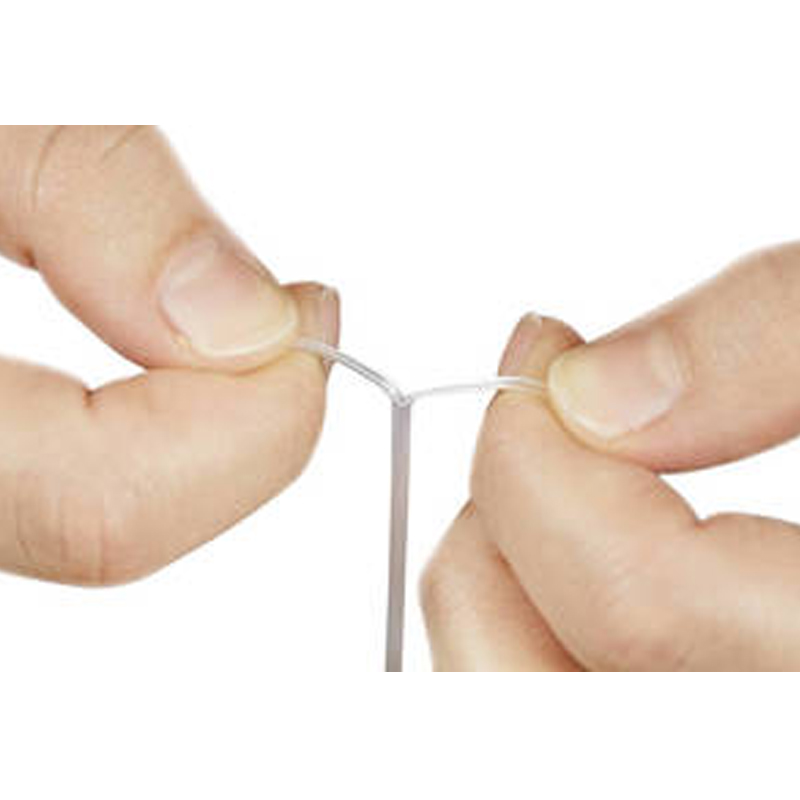

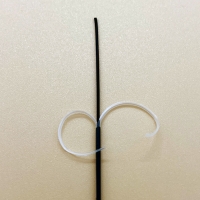

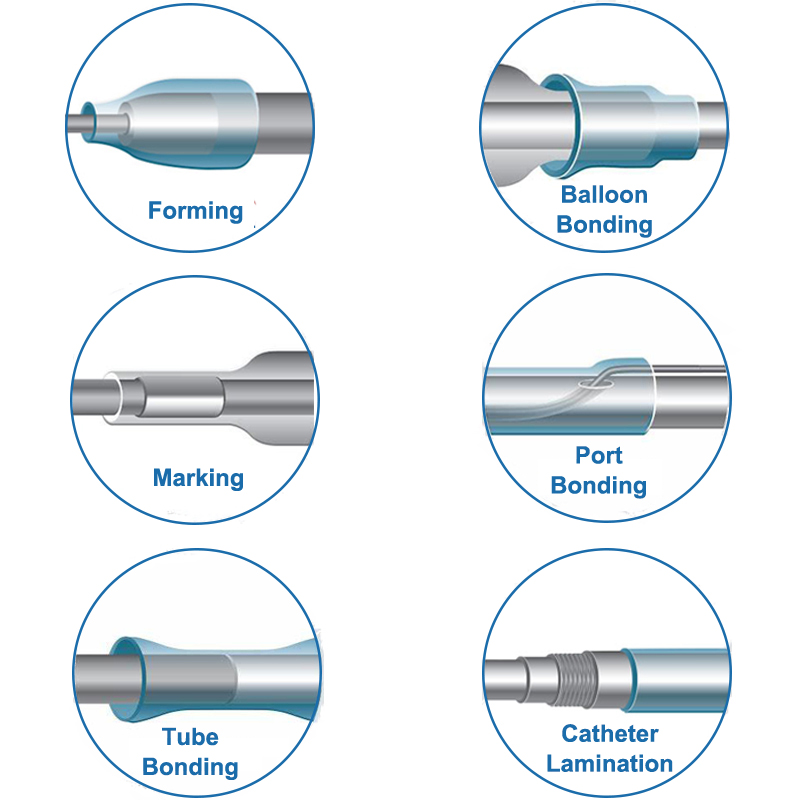

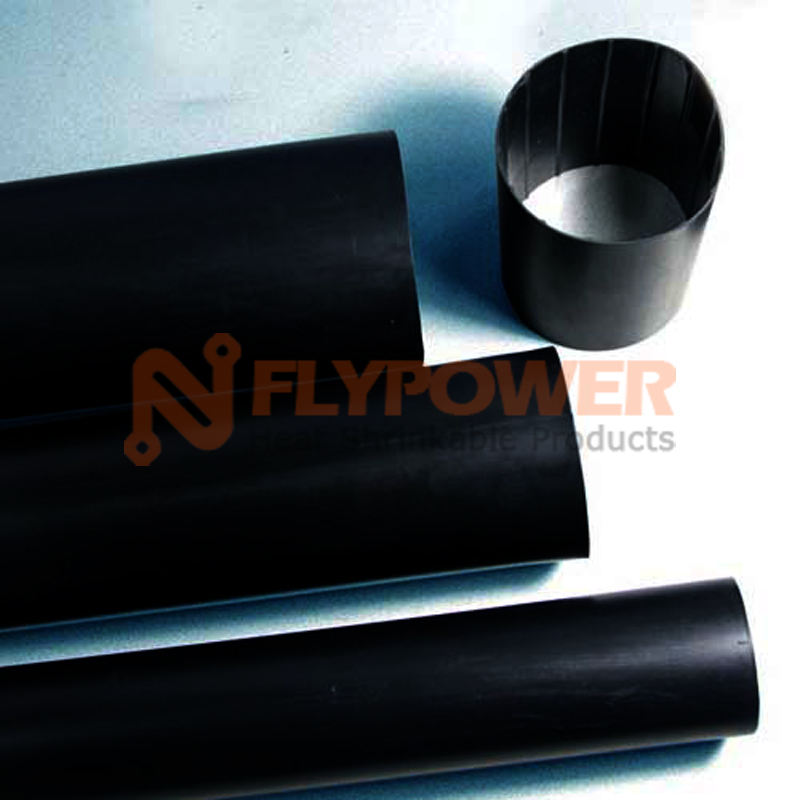

BH-MT-PET-CB medical grade ultra thin wall PET (Polyester) heat shrink tubes-round type is made of medical grade Polyethylene terephthalate. Suitable for insulation of medical devices, variable-stiffness catheters, protective covering/coating and bundling, reinforcement, tip forming, tube making and printing, and electrical insulation. Its tough material hardness and ultra-thin wall thickness can fully protect extremely fine products without being affected by thickness.

KEY FEATURES

? Shrink Ratio: 1.3:1 and 1.6:1

? Thin wall, high tensile strength, high Dielectric strength

? Low shrinkage temperature

? Resistant to most chemicals and oils

? Can be printed using conventional techniques

? Inner diameter before heat shrinking: 0.3-8mm

? Wall thickness before heat shrinking: 0.0064-0.05mm

APPLICATIONS

? Variable-stiffness catherters

? Protective covering/coating & bunding

? Reinforcement

? Tube marking & printing

? Electrical insulation

? Tube forming